Most Americans, at some point in their lives, will have to undergo surgery for some reason or another. Surgery can be intimidating, scary, and even deadly. How do you know that the scalpel the surgeon is using is clean of bacteria and infectious disease? Can you be sure?

One sterilization company’s existence depends on it. As a sterilization chamber, they work with many pharmaceutical manufacturers. One such customer uses Ethylene Oxide (ETO) to sterilize the surgical equipment that they manufacture. They find that this is the most effective way of killing bacteria, mold, and fungi that would, if unchecked, prevent their bandages, sutures, and other surgical equipment from being suitable for use. 100% sterilization 100% of the time is the only way for the sterilization chamber to continue being successful in business.

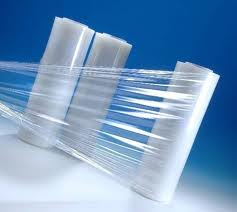

One hindrance that has been cause for worry is solid film. In order to ensure that a load is 100% sterile, the gas must be able to penetrate the pallet completely. A solid film prevents this from happening. However, allowing the gas to penetrate is only half of the problem. Aeration is also necessary. Although ethylene oxide is an effective sterilizer, it has a number of unpleasant characteristics. Not only is it flammable, it is also highly toxic and is actually classified as a carcinogen. Trapped pockets of Ethylene Oxide, no matter how small, could potentially be lethal; therefore it is critical that the gas be allowed to escape once it has finished its job. A solid film actually hampers this, acting as a barrier during the flushing process. Where can sterilization chambers like this one find an alternative to solid film?

IPS Packaging helped alleviate this issue by providing the sterilization chamber with stretch film! The level of aeration that it provides ensures that the Ethylene Oxide can effectively penetrate and then, once the load is sterilized, escape. Stretch film is also compatible with many company’s existing machinery…this makes the switch from their existing film very feasible. Who knew?!

The Problem: A sterilization company for medical products and pharmeceutical manufacturers was struggling with th hindrance of solid film for packaging.

- Solid film prevents gas from penetrating pallet and sterilizing it

- Lack of proper aeration of product

The Solution: IPS Packaging helped alleviate the company's issue by providing the sterilization chamber with stretch film

- Proper level of aeration

- Use of stretch film in sterilization chamber

- Stretch film compatible with many company's machinery