IPS Packaging’s hand tensioners allow operators to bring strap to desired tension with minimal interruption, effort, and strap waste.

Most tensioners have a base which goes under the strapping and rests on the flat surface of the object being strapped. For smaller or irregular bundles, a push-type tensioner, which has no base under the strap is advised.

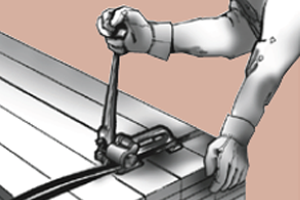

Feedwheel, General Use

Feedwheel, General Use

The feedwheel tensioner uses a serrated feedwheel which engages the strapping firmly. There is no limit to the amount of slack it can pull out of the strap. Fast and easy to use, it requires the use of painted and waxed strapping.

Windlass, Heavy Duty Applications

Windlass, Heavy Duty Applications

The windlass tensioner simply winds one end of the strapping around a slotted windlass shaft. Used with dry, heavier strapping precut to desired lengths.

Rack and Pinion, Heavy Round or Irregular Applications

Rack and Pinion, Heavy Round or Irregular Applications

The rack-and-pinion tensioner uses a serrated gripping dog to clasp the pulled strap end. It can be used with either dry or lubricated strapping on round or irregular shaped packages. This tensioner has limited take-up.