Corrugated box dimensions

Let's take a look at how to measure corrugated boxes so you know how much room you have for your product and packaging supplies.

How to Measure Box Dimensions (Exterior)

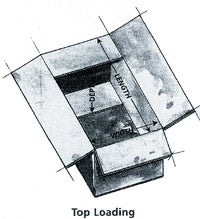

Unless otherwise specified, all dimensions are expressed as internal dimensions in inches as follows:

Length (L) = the longer dimension at the opening

Width (W) = the shorter dimension at the opening

Height (H) = the dimension from the top of the opening to the base

How to Measure Boxes Dimension (Interior)

Dimensions are given in the sequence of length, width and depth. Internationally, the words length, breadth, and height may be used to express these dimensions. The dimensions of a box are expressed based on the opening of an assembled box, which can be located on the top or the side, depending on how it is to be filled. The opening of a box is a rectangle; that is, it has two sets of parallel sides. The longer of the two sides is considered its length, the shorter of the two sides is considered its width. The side perpendicular to length and width is considered the depth of the box. Dimensions can be precise for either the inside or the outside of the box. Exact inside proportions must be deliberated to ensure the proper fit for the product being shipped or stored. At the same time, palletizing and distributing the boxes relies on the outside dimensions. The box manufacturer should be knowledgeable as to which dimension is most important to the customer.

Dimensions are given in the sequence of length, width and depth. Internationally, the words length, breadth, and height may be used to express these dimensions. The dimensions of a box are expressed based on the opening of an assembled box, which can be located on the top or the side, depending on how it is to be filled. The opening of a box is a rectangle; that is, it has two sets of parallel sides. The longer of the two sides is considered its length, the shorter of the two sides is considered its width. The side perpendicular to length and width is considered the depth of the box. Dimensions can be precise for either the inside or the outside of the box. Exact inside proportions must be deliberated to ensure the proper fit for the product being shipped or stored. At the same time, palletizing and distributing the boxes relies on the outside dimensions. The box manufacturer should be knowledgeable as to which dimension is most important to the customer.McKee also created a simpler formula based on caliper of the combined board rather than of bending stiffness:

It provides accuracy close to the original equation and is easier apply, both in testing and mathematically. McKee's work was based on averages. Individual boxes will vary above and below the predicted value. The ability to predict the compression strength of a container is a considerable tool, but it is even more powerful to take a compression requirement, back out an ECT requirement and use it to determine suitable board combinations. Solving for Ea, the simplified McKee formula is:

It provides accuracy close to the original equation and is easier apply, both in testing and mathematically. McKee's work was based on averages. Individual boxes will vary above and below the predicted value. The ability to predict the compression strength of a container is a considerable tool, but it is even more powerful to take a compression requirement, back out an ECT requirement and use it to determine suitable board combinations. Solving for Ea, the simplified McKee formula is:

ECT = BCT ÷[5.87 x √(caliper of combined board x box perimeter)]

Distribution Environment and Container Performance

The ability of a container to perform in distribution is considerably impacted by the circumstances it encounters during the cycle. Some of these conditions are tricky for the packaging engineer to manipulate, including stacking time and relative humidity. Others are determined by handling and unitizing packages; for example, pallet patterns, pallet overhang, pallet deck board gaps and excessive handling. We can now estimate the impact of these conditions on container strength. If the original box compression strength is known (determined in the lab using a dynamic compression tester), we can figure it by generally accepted multipliers to arrive at an estimated maximum safe stacking strength.

The ability of a container to perform in distribution is considerably impacted by the circumstances it encounters during the cycle. Some of these conditions are tricky for the packaging engineer to manipulate, including stacking time and relative humidity. Others are determined by handling and unitizing packages; for example, pallet patterns, pallet overhang, pallet deck board gaps and excessive handling. We can now estimate the impact of these conditions on container strength. If the original box compression strength is known (determined in the lab using a dynamic compression tester), we can figure it by generally accepted multipliers to arrive at an estimated maximum safe stacking strength.

Environmental Factors

| Environmental Factors | Compression Loss | Multipliers | |

|---|---|---|---|

| Storage time under load | 10 days-37 percent loss | .63 | |

| 30 days-40 percent loss | .6 | ||

| 90 days-45 percent loss | .55 | ||

| 180 days-50 percent loss | .5 | ||

| Relative humidity, under load (cyclical RH variation further increases compressive loss) | 50 percent-"--0 percent loss | 1 | |

| 60 percent-10 percent loss | .9 | ||

| 70 percent-20 percent loss | .8 | ||

| 80 percent-32 percent loss | .68 | ||

| 90 percent-52 percent loss | .48 | ||

| 100 percent-85 percent loss | .15 | ||

| Pallet Patterns | Best Case | Worst case | |

| Columnar, aligned | Negligible loss | .9 | .85 |

| Columnar, misaligned | 10-15 percent loss | .6 | .4 |

| Interlocked | 40-60 percent loss | .8 | .6 |

| Pallet deckboard gap | 10-25 percent loss | .9 | .75 |

| Excessive handling | 10-40 percent loss | .9 | .6 |

See also: