- 800-277-7007

- ISO 9001:2015 Certified Company

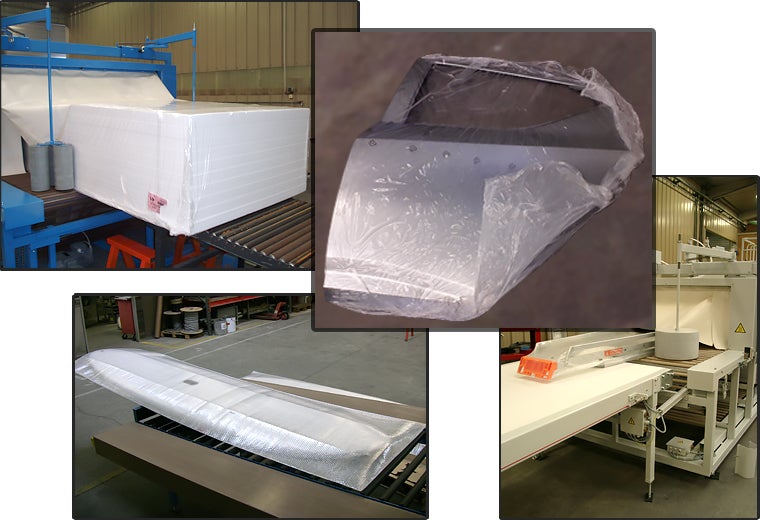

Wrapping Unit

FARBAL wrapping units come standard with sealing bars ranging from 750 to 4000 mm and accommodate loads between 100 and 1100 mm high. They adapt to various throughput rates, utilizing heat bars for rapid or slow processing. Thermostatic control ensures efficient sealing and cutting, tailored to each customer's requirements for a precise, modular solution. Some models offer optional cooling jigs.

Shrink Tunnels

FARBAL shrink tunnels boast high output and superb thermal insulation. They utilize mobile bar or grid conveyor belts, offering adjustable speeds from 2 to 30 meters per minute and power ranging from 12 to 120 kW. These tunnels accommodate various package heights (200 to 1400 mm) and widths (400 to 3500 mm).

Side Sealing Units

FARBAL side sealing units create side seals on lengths ranging from 750 to 3500 mm, cutting the film accordingly. Width adjustment can be manual or automatic. These units share the advanced technology of sleeve wrapping machines. They accommodate different throughput rates with heat bars, ensuring efficient sealing and cutting without material or time loss.

Side Cutting Units

FARBAL side cutting units feature metal slitting saws to trim excess film continuously from load sides. They require no manual adjustment; product width is detected by photo-electric cells, and length is automatically managed. This innovative system allows for packaging products of different widths and heights using the same polyethylene film roll efficiently.

Conveyors

FARBAL conveyors, designed by our Engineering Office and assembled by our technicians, ensure flawless film packaging. They come in various configurations including motorized, smooth or non-slip belts, motorized or gravity-driven rollers, and chain conveyors. Additionally, they can incorporate features like work tables, tilting mechanisms, angle adjustments, and curved designs to suit diverse production needs.

Unwinders On The Floor

FARBAL floor unwinders, positioned at a 90° angle along the packaging line, offer efficiency and safety. Ideal for high-speed packaging, they ensure operator comfort and prevent musculoskeletal disorders by eliminating the need to work at height during reel changes. With options for single or double units, integrated reel storage, and manual or semi-automatic splicing, they enhance productivity and ergonomics while protecting the environment.

Electrical Cabinets

FARBAL's electrical cabinets provide safe power supply to machines, designed, assembled, and wired in-house by our experts. Tailored to each customer's needs, we develop optimized industrial solutions in collaboration with our partners, ensuring efficient and secure operations for every application.

Handling and Miscellaneous Adaptations

FARBAL offers a diverse array of pre- and post-packaging line accessories including cushioning, alignment, knocking up, and rotation devices. Additionally, it accommodates customer requests for special adaptations like automatic film change and compression systems, ensuring tailored solutions to optimize packaging processes.

Clamping Cylinders

The LSE clamping cylinder intensifies air-oil pressure, enabling powerful forces in compact setups with minimal air usage. With an operating temperature range of +10° to +80°C, it's versatile. Supported by filtered, lubricated air, it ensures efficient performance, ideal for diverse industrial applications.

Your Customized Solution Sectors

Our tailored packaging machines cater to diverse sectors, offering bespoke solutions to meet specific industry needs. From automotive to garden furniture and beyond, we design and manufacture machines optimized for each sector's unique requirements, ensuring efficiency, reliability, and compliance with industry standards.

- Bedding

- Joinery items

- Furniture

- Garden furniture

- Automotive

- Radiator

- Building materials

- Equipment

- Signs

- Sport and leisure

- Logistics and Internet

- Miscellaneous